FLAMAL™ for Oxy-fuel Cutting and Heating

High performance solutions for the metal fabrication industry.

When used for cutting, brazing, metalizing and heating applications, FLAMAL™ combines the best performance characteristics of Acetylene with the safety of Propane to produce superior results. We offer high purity, quality assured and continuous supply for your applications.

Our Complete Offer

Ready to support your metal fabrication.

-

Heat Treatment Solutions

FLAMAL™ solutions -

Product Packaging

< 500 Nm³ to 500,000 m³ per month

-

Technical Expertise

Contact Us

FLAMAL™

Used for oxy-fuel applications such as cutting and heating.

| Application | Suitable Gases | FLAMAL™ Solution | |||

|---|---|---|---|---|---|

| Flame Cutting | Propylene (C₃H₆) | FLAMAL™ 29 | |||

| Acetylene (C₂H₂) | Acetylene | ||||

| Oxygen (O₂) | Oxygen | ||||

| Gas Welding | Acetylene (C₂H₂) | Acetylene | |||

| Soldering, Brazing and Braze Welding | Propylene (C₃H₆) | FLAMAL™ 29 | |||

| Acetylene (C₂H₂) | Acetylene | ||||

| Propane (C₃H₈) | Propane | ||||

| Oxygen (O₂) | Oxygen | ||||

| Heating, Bending and Straightening | Propylene (C₃H₆) | FLAMAL™ 29 | |||

| Propane (C₃H₈) | Propane | ||||

| Oxygen (O₂) | Oxygen | ||||

| Flame Hardening | Propylene (C₃H₆) | FLAMAL™ 29 | |||

| Acetylene (C₂H₂) | Acetylene | ||||

| Thermal Spray | Propylene (C₃H₆) | FLAMAL™ 29 | |||

| Acetylene (C₂H₂) | Acetylene |

FLAMAL™ Properties

| FLAMAL™ | |||||||

|---|---|---|---|---|---|---|---|

| Acetylene | FLAMAL™ 29 | Propane | Natural Gas | ||||

| Safety Data | C₂H₄ | C₃H₆ | C₃H₈ | CH₄ | |||

| Shock sensitivity | Unstable | Stable | Stable | Stable | |||

| Explosive Limits in Air (%) | 2.2 - 80 | 2.0 - 10.5 | 2.2 - 9.5 | 5.0 - 15 | |||

| Maximum Allowable Use Pressure, kPa (psig) | 103 (15) | Cylinder | Cylinder | Line | |||

| Burning Velocity in Oxygen, m/s (ft/s) | 7.6 (24.9) | 3.90 (12.8) | 3.31 (10.9) | 3.90 (12.8) | |||

| Backfire Tendency | High | Low | Low | Low | |||

| Toxicity | Low | Low | Low | Low | |||

| Physical Properties | |||||||

| Specific Gravity of Liquid (water =1) | - | 0.522 | 0.507 | - | |||

| Weight of Liquid, kg/L (lb/gal (US)) | - | 0.52 (4.35) | 0.51 (4.28) | - | |||

| Specific Volume, m³/kg (ft³/lb) | 0.91 (14.6) | 0.56 (9.06) | 0.54 (8.66) | 1.47 (23.6) | |||

| Specific Gravity of Gas (air = 1) | 0.906 | 1.48 | 1.52 | 0.62 | |||

| Cylinder Pressure at 21°C (70°F) kPa (psig) | 1724 (250) | 931 (135) | 827 (120) | - | |||

| Boiling Point, °C (°F) at atm pressure | -83.8 (-118.8) | -47.7 (-53.8) | -42 (-43.6) | -161.5 (-258.7) | |||

| Heating Values | |||||||

| Neutral Flame Temperature, °C (°F) | 3087 (5589) | 2867 (5193) | 2526 (4579) | 2538 (4600) | |||

| Heat Emission, BTU/ft³ | primary flame | 507 | 433 | 255 | 11 | ||

| secondary flame | 963 | 1,938 | 2,243 | 989 | |||

| Total BTU/ft³ | 1,470 | 2,371 | 2,498 | 1,000 | |||

| Total Heat Value, BTU/lb | 21,500 | 21,500 | 21,600 | 23,600 | |||

Product Packaging Options

We offer flexibility in supply to match your needs.

|

Cylinder |

Pack |

Microbulk |

Bulk |

|||

|---|---|---|---|---|---|---|

| Monthly Consumption Rate To be used for reference only |

up to 500 Nm³ |

up to 1,000 Nm³ |

up to 5,000 Nm³ |

up to 500, 000 Nm³ |

||

Premium Cylinder TOPs

Focusing on simplicity and safety.

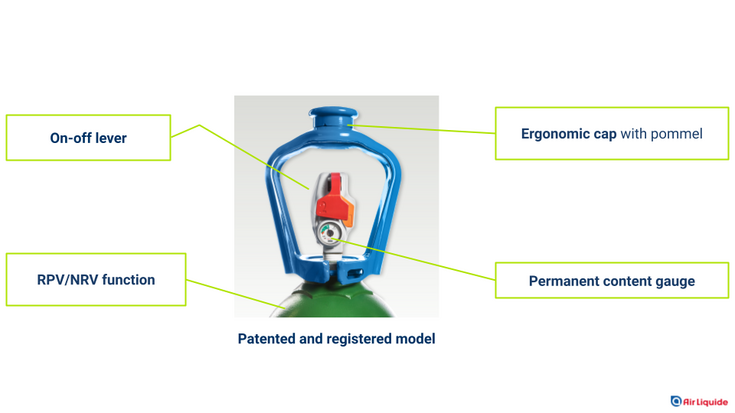

Our Patented SMARTOP™ Cylinder Cap

A smart residual pressure valve with on/off lever and a permanent content gauge.

- Smooth and safe opening and immediate gas cut-off

- Ergonomic cap with pommel for easy handling

- Gas content monitoring at a glance

- Prevents back-flow contamination

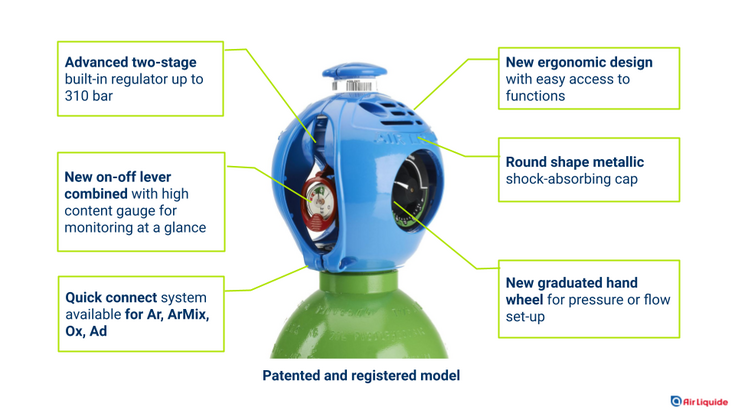

Our Advanced EXELTOP™ Cylinder Cap

An advanced two-stage built-in regulator with on/off lever.

- No need for a separate regulator

- No gas loss and gas content monitoring at a glance

- Quick connect for all gases

- Key safety features

- Intuitive to use

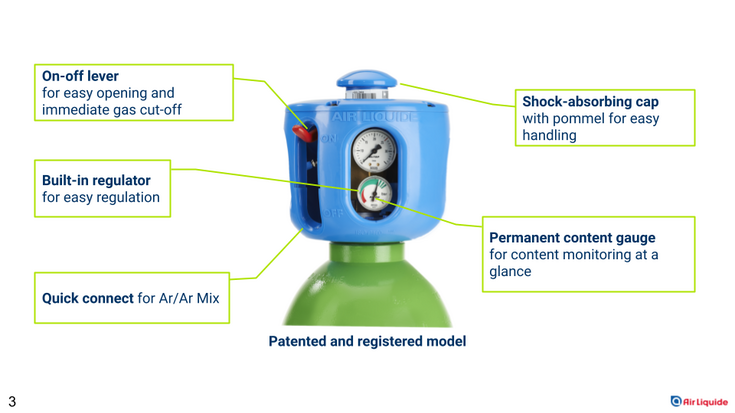

The Original ALTOP™ Cylinder Cap

A smart residual pressure valve with on/off lever and a permanent content gauge.

- Permanently protected valve for improved safety

- Easy on/off lever

- Gas content monitoring at a glance

- Pommel and grab handle for easy cylinder handling

Contact Us

Let our experts get back to you.